| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Deshisen

Model Number : HM1300

Certification : CE

Place of Origin : SHENZHEN CHINA

MOQ : 1 set

Price : Negotiation

Supply Ability : The spot goods

Packaging Details : Wooden packaging

Power : 18 KW (380V AC 3φ 50Hz)

Warranty : One Year

Weight : 1600kg

Usage : Packaging, Corrugated Box, Making Carton, chemical, CORRUGATING CARDBOARD

The highest speed : 60m/min-100m/min

Color : Polar grey , orange

Driven Type : Electric

Corrugated Cardboard Boxes / Zipper Shipping Boxes Machine / Size 1300mm×1050mm

product description:

Full automatic stick double-sided adhesive machine is designed and researched by Deshisen CO., Ltd for single sheet water-based printing of corrugated container, Offset printing color-mounted corrugated cardboard boxes, cardboard color boxes, etc., affixed with double-sided tape and easy-to-tear tape simultaneously.

Any type of coding system can be set up on the platform for variable information printing, and a labeling head can be optionally installed. Local labeling function can be installed as well.

This series adopts a more optimized modular design, users can have more personalized choices, and achieve a multi-purpose design concept.

This equipment is widely used in pharmaceutical packaging, food packaging, logistics packaging, gift box packaging and other fields.

Advantages:

This machine can be added with a shell, which is not only beautiful, but also has a protective effect.As shown below .

E-commerce special zipper carton third generation glue process

Compared with the first generation of double-sided glue, the second generation of foam glue two adhesive materials, the third generation of technology advantages are very obvious.

1, 10000 meters long endurance, production efficiency increased by 35%.

2, hot melt adhesive material cost is 40% of double-sided adhesive.

3, environmental protection degradation (double-sided adhesive can not be completely degraded).

Product parameters:

| Model | HM1300 | Working width | 1310MM |

| material | ≥300g/m²cartons | Air compressor | min. 6 bar |

| Minimum paper size | 250mm×250mm | total power | 18 KW (380V AC 3φ 50Hz) |

| Maximum paper size | 1300mm×1050mm | weight | 1600KG |

| The highest speed | 60m/min-100m/min | Machine dimensions | 6600*2100*1600 |

List of vulnerable parts:

| model | picture | quantity | unit | Notes |

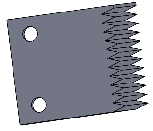

| Tooth blade (15 teeth) |  | 4 | slice | |

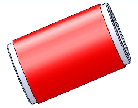

| Press wheel + wrap adhesive |  | 4 | piece | |

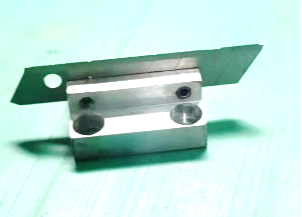

| The flat cutter |  | 2 | piece | |

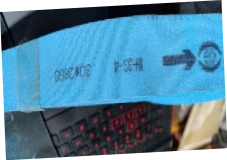

| The belt |  | 1 | piece |

Feature:

1.The machine is running steady with strengthened driving system, and it is also easy for maintenance.

2.The motor is controlled by a transducer (inventer) which is available for automatic timing. It is power saved and helps to work stably.

3.An electric adjusting system in the machine makes it more conveniently when adjusting the space of carriers which usually based on the double-face tooth rods adjusting system.

4.Feeder is controlled by a separated motor. Paper is usually feed by several thick belts under the help of vibration motor. Feeding is continuous,exact and automatic with this system.

5.Grinders are provided in both sides of machine, to make gluing more stable and firm.

6.Two sets of gluing units: top unit for bottom glue and lower unit for the side glue. All standard glue units apply line glue. Space adjustment is through the tooth rods.

7.PLC system and touch screen for easy operation. Out-put quantity/speed/counting etc., is able to set by this system. A remote diagnosis helps to maintenance (remote controller system included), and a photo electric system for speed control in pressing unit (speed in pressing unit is corresponding automatically with the one in feeding unit). Counting through photo-electric sensor & electromagnet kicking.

Pre-sales service:

1.We provide presales service in various forms, making investment budge, manufacturing, planning, so that customers can make a reasonable plan with less cost.

2.We will fist check customer’s goods and goods size, then we will recommend suitable wrapping machine to 100% suitable.

3.We will recommend and offer machine according to customer’s use and purchase budget.

In-sale service:

1.We will supply each manufacturing step photo for customer checking on time.

2.We will prepare packing and shipment according to customer’s needing in advance.

3.Testing the machine and making video for customer’s checking.

After-sale service:

1.We will guarantee the machine quality for 1 years.

2.We provide free training and answer customer's question on technology in time.

|

|

Electric Carton Inspection Machine 100m/min For 1300mm×1050mm Paper Images |